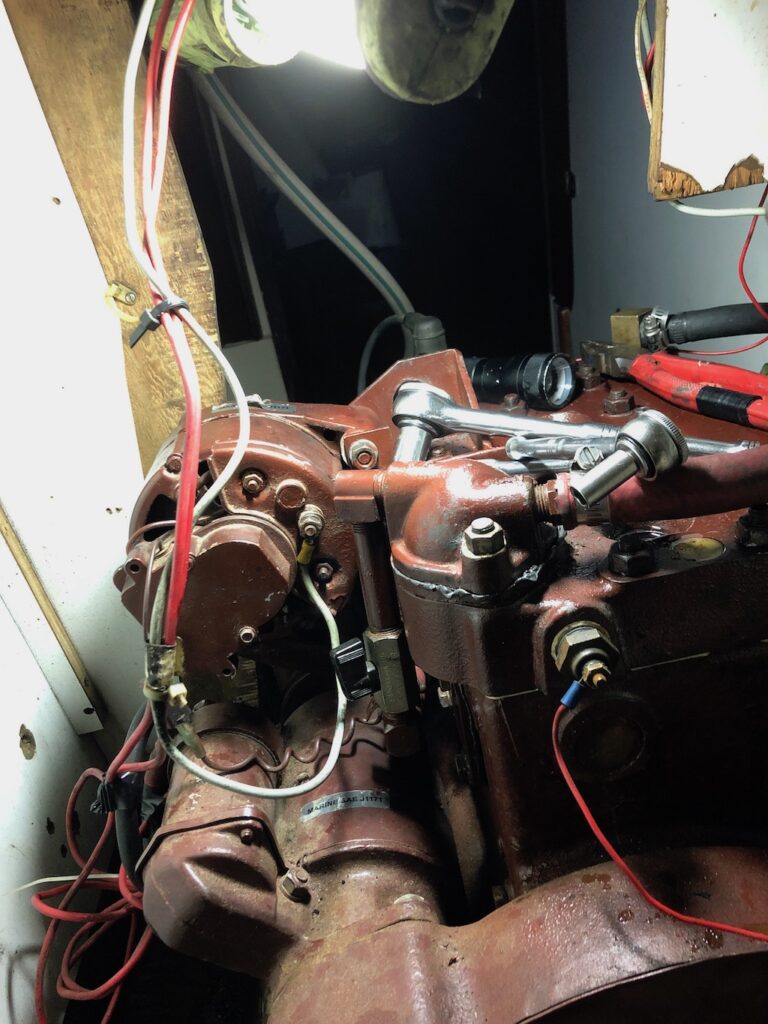

We bought the boat with a dead engine. It wasn’t seized, but would not fire up. After testing, all 4 cylinders had no compression. I have not seen that before in all my past engine mishaps and repairs. I was left scratching my head. I had to tear the head off the engine to begin this rebuild.

It was an Atomic 4 gas engine, recently refurbished by Moyer Marine so it didn’t make sense that something major was wrong. This video is showing what I found, and the oil changes, and subsequent exhaust repair as well once I got it running.

It took an hour or so to get the head off, and found that the head gasket was blown between cyl 1 and 2 and blown between 3 and 4, so that answered the riddle as to why each cylinder had no compression.

I actually had 2 spare head gaskets so I put them in, according to the Moyer Marine Atomic 4 engine manual, you need to put 2 in to get the right thickness from the original gasket.

I cleaned up as mush as I easily could, and used my Audi high temperature gasket silicon to create new gaskets for the inspection plate and the thermostat etc.

I believe that the major defect was that the previous owner had not used a water muffler exhaust and there was no protection against back flow. If the engine didn’t start, and the impeller was throwing water into the exhaust, then after cranking a while, there was nothing in place to stop the water from backing into the exhaust manifold and ultimately into the cylinders. Water doesn’t compress, hence the blown gasket.

I found water in the oil pan, and did 5 oil changes to get the water out.

I guess some people just are not very mechanical, but it makes sense if you think about it. Someone removed the water muffler and it was only a straight pipe back out the thru-hull. This was a self induced problem. Going forward, what I did to give me some protection was install a water shutoff ball valve between the intake thru-hull and the impeller, and would start the motor with it off, and when it started, then open up the ball valve and check the exhaust to make sure I saw water coming out. This worked great, removed the chance of flooding the manifold and I went through the 1st season in the water with it like this.

I ended up motoring about 3 hours to get into Toronto during a period of no wind and the trip really smoothed out this motor.

Brought back to life!

Recent Comments